Approach

We make machines, equipment and assemblies from metal and plastic on a subcontract basis in our factory in Jiashan (China). We are able to work from drawings or a physical model.

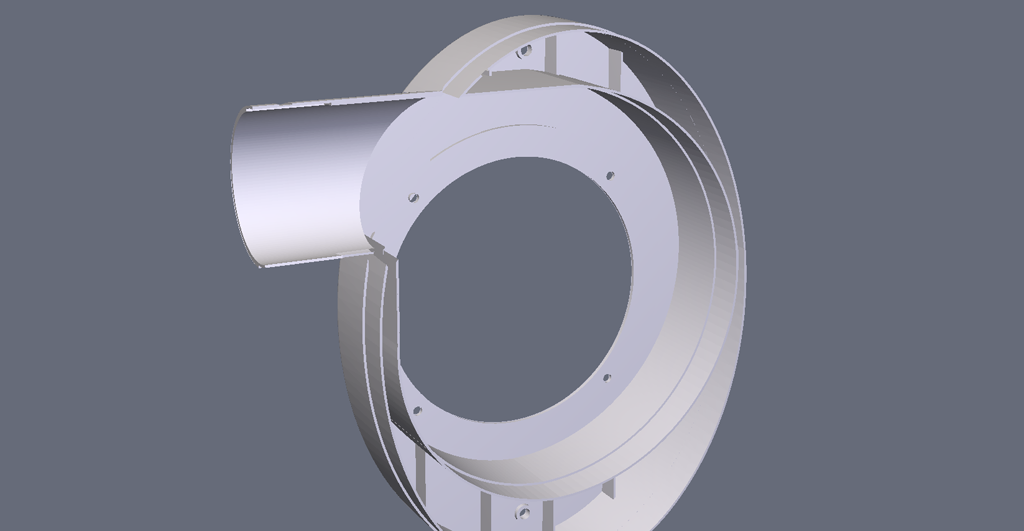

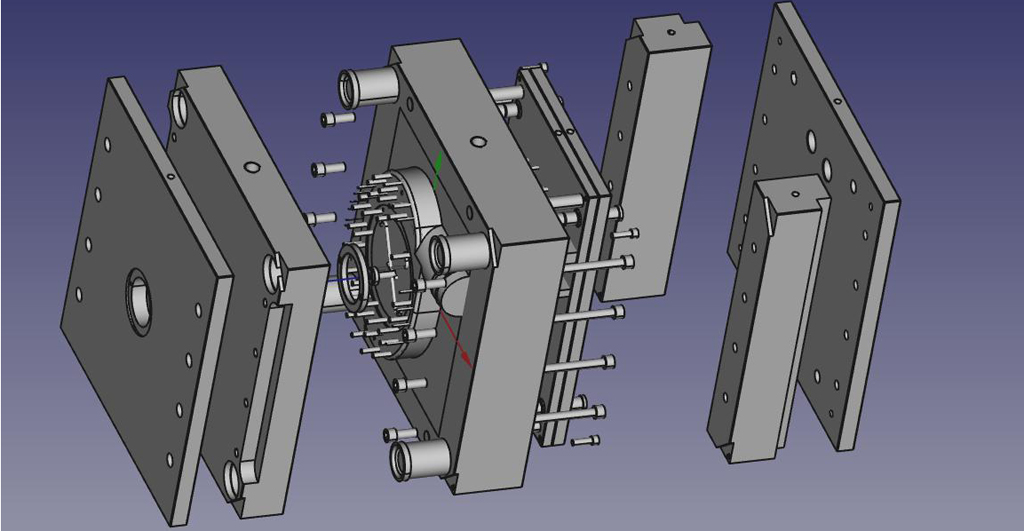

Tooling en samples

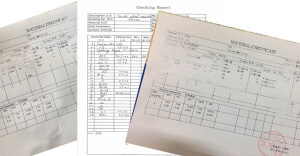

First, we have the tooling for metal and plastic products made. Next, this tooling is used to manufacture the initial samples. We send the samples and the associated First Article Inspection Reports to you by air freight.

Trial series

After receiving your approval, we will proceed with the first trial series. A first and last sample report will be generated for this series (as a minimum). The additional semi-manufactured products and bought-in items are purchased in China. All the components will be assembled and tested in our factory. At the end of the process, the products are packed in boxes together with the user manuals and labelled correctly. Finally, we generate work instructions and checklists. This ensures that our experiences with the trial series are documented for future batches.

1st series

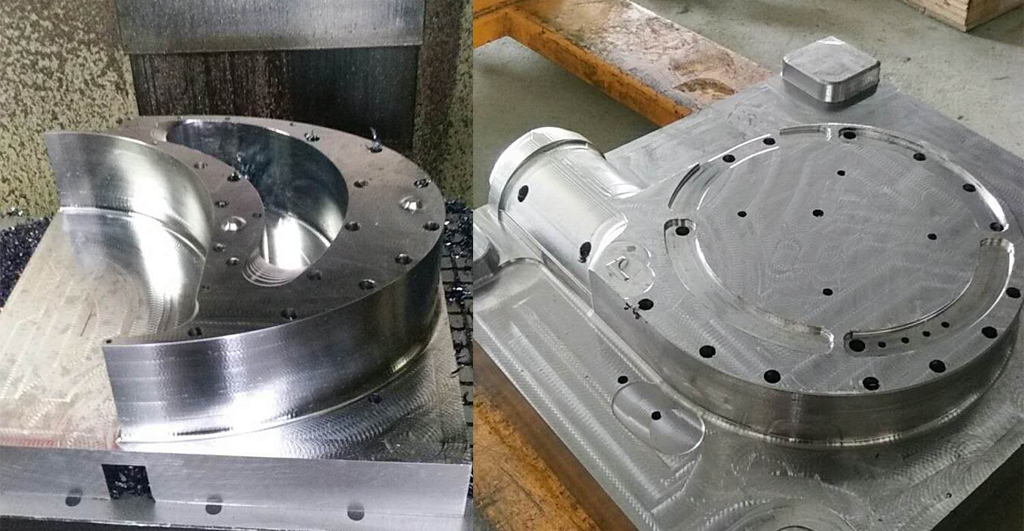

Series manufacture starts up at our suppliers. The products are only sent to Jiashan after they have been approved by our inspectors. In Jiashan, an experienced team assembles the components in our own factory. In our view, assembly is a critical step. It allows us to determine whether all the approved components can be assembled to manufacture a functional product. Finally, we produce designs for the required assembly tools and jigs.

Manufacture

Series manufacture is now up and running at full speed and regular checks are performed. The aids and jigs (assembly/checking) are ready and used during assembly. From this point on, we can deliver on demand from our central warehouse in China or the Netherlands.

If you would like more information about manufacturing your products in China by D&D Production & Sourcing, please click here.